- Efficiency Advantage

- Starting Current Advantage

- Speed Advantage

- Reliability Advantage

- Quiet Advantage

- Ease of Operations Advantage

- Performance Advantage

- Service Advantage

- Single stage compressor design

- Optimized impeller designs

- High efficiency, refrigerant cooled motors

- Free standing Variable Frequency Drive

- Frictionless compressor bearings minimize efficiency Loss

- Easily meeting BEE 5–Star Rating : ISEER 9.87 to 10.0

- IPLV @ AHRI conditions < 0.30 IkW/TR

- Capable of operating at a high lift conditions, such as high condensing or low leaving chilled water

- Starting Amps - 2 Ampere as against 200 ~500 A of conventional chillers

- There is gradual increase in the voltage until the DC bus reaches the up trip voltage

- Combination of soft start function and variable speed drive combined, limits inrush current at Start up

- Starting Amps - 2 Ampere as against 200 ~500 A of conventional chillers

- There is gradual increase in the voltage until the DC bus reaches the up trip voltage

- Combination of soft start function and variable speed drive combined, limits inrush current at Start up

- Over a period of time, oil in chillers with lubricated compressors tends to carry over to the heat exchangers and coat the heat exchanger tubes and reduce heat transfer, resulting in a deterioration in chiller efficiency.

- An ASHRAE determined the quantity of oil as a percentage of refrigerant in older chillers and found the average to be 12.88%. The study determined that even 3.5% of oil equated to an 8% efficiency loss.

- Thus, oil free compressors stand to benefit to a large extent due to the absence of oil

- Bearings capable of handling high thrust & radial loads, can handle any shocks / surge conditions without damage

- Permanent Magnet Motor, designed for 20,000 rpm speed, capable of easily handling power fluctuations

- VFD designed for high switching frequency considering the requirements of Permanent Magnet motor

- Precise stepper motor driven IGV operation with runtime auto calibration

- Totally enclosed IGV operating mechanism

- Sine Wave filters used to smoothen the power supply, minimizes the effect of voltage fluctuations

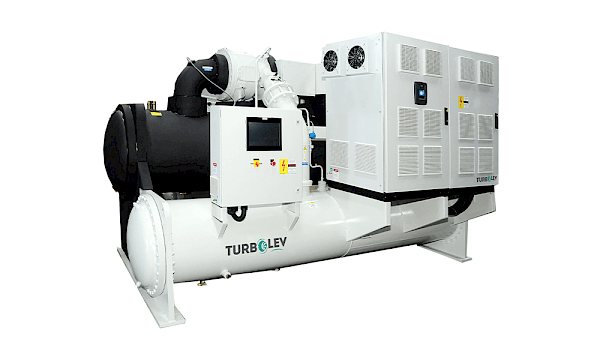

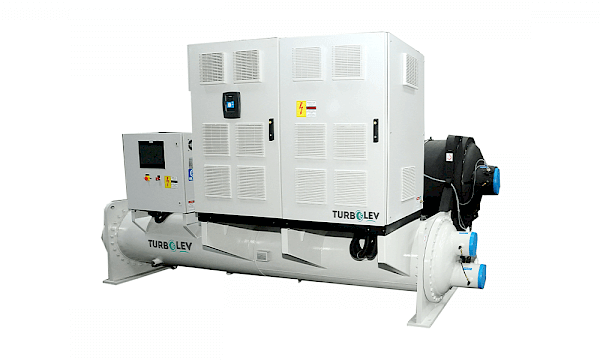

MODEL

| Chiller Range | Evaporator Model | Condenser Model | Overall height (mm) | Overall width (mm) | Overall length (mm) | Shipping weight (kg) | Operation weight (kg) |

| KSM 400 TR – 600 TR |

2612 | 2212 | 2290 | 2090 | 4435 | 6590 | 6810 |

| 2612 | 2612 | 2285 | 2040 | 4435 | 6720 | 7020 | |

| 3012 | 2612 | 2320 | 2140 | 4470 | 7560 | 8000 | |

| 3012 | 3012 | 2440 | 2210 | 4470 | 8290 | 8820 | |

| 3612 | 3012 | 2450 | 2370 | 4485 | 9230 | 10030 | |

| 3612 | 3612 | 2595 | 2445 | 4485 | 10150 | 11270 | |

| KDM 800 TR – 1200 TR |

3016 | 3016 | 2440 | 1865 | 5720 | 11080 | 11230 |

| 3616 | 3016 | 2450 | 2030 | 5730 | 12680 | 41450 | |

| 3616 | 3616 | 2595 | 2185 | 5730 | 14160 | 16010 | |

| 4216 | 3616 | 2650 | 2330 | 5850 | 17850 | 20450 | |

| 4216 | 4216 | 2845 | 2470 | 5850 | 19310 | 22430 |