- Current Advantage

- Speed Advantage

- Reliability Advantage

- Quiet Advantage

- Ease of Operations Advantage

- Performance Advantage

- Service Advantage

- Two stage compressor design

- Optimized impeller designs

- High efficiency, refrigerant cooled motors

- Inbuilt variable frequency drive

- Flooded design evaporators

- Oil free compressor minimizes Efficiency Loss

- An ASHRAE determined the average quantity of oil as a percentage of in older chiller. This found the average to be 12.88%

- A study determined that even at 3.5% of oil equated to an 8% efficiency loss

- Advance component designs - Internally and externally enhanced copper tube for high heat transfer coefficients

- Options of alternative materials - Cupro Nickel for sea water / corrosive applications

- Combination of Inlet Guide Vane and VFD control

- Excellent stability at lower loads

- Active surge control - avoid surging by appropriate movement of shaft by using inbuilt surge control algorithm

- Electronic expansion Valve provides superior refrigerant flow control over a range of operating conditions

- Provides excellent part of load efficiency

- All chillers are designed to offer very high reliability during the entire life spam of chiller

- The reliability built into the design of every components of the chiller

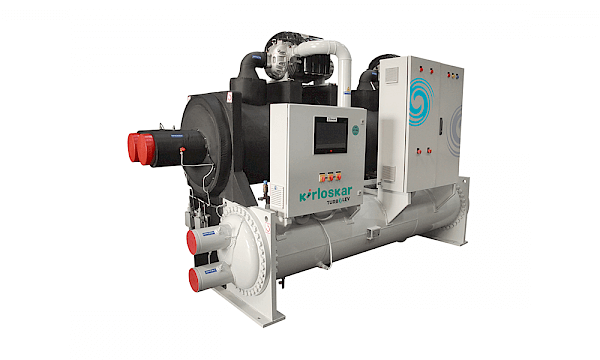

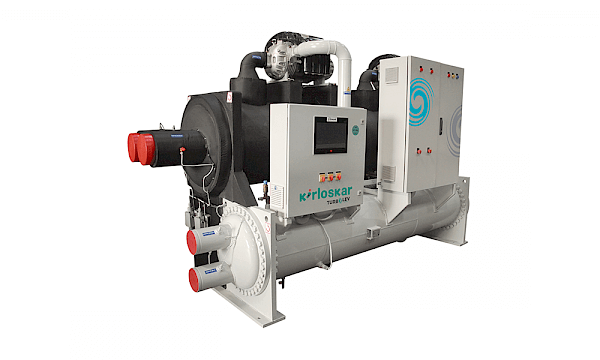

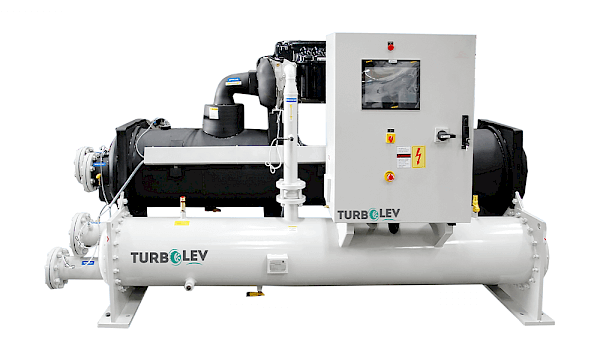

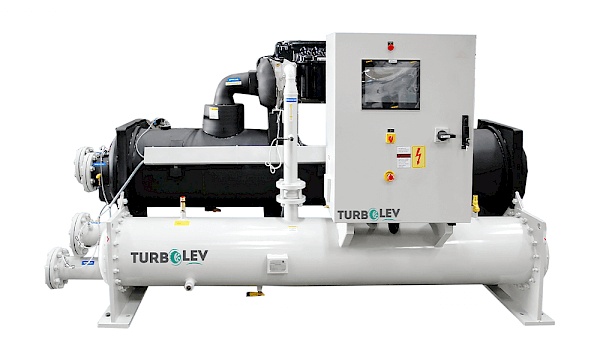

- Design features + precision components makes Kirloskar TurboLev® Centrifugal Chillers the best in terms of reliability and efficiency

- High speed allowing for size and weight reduction

- Magnetic bearings with no friction increases life of the compressor

- Lower vibrations levels

- The compressor speed adjusts automatically to match the load and current operating conditions so that optimum efficiency is gained

- High speed shaft - Maximum RPM 48,000

- The rotor shaft is held in position with ten separately controlled electro magnetic cushions which continually change in strength to keep the shaft centrally positioned

- Sensors monitor the position of the shaft over 6 million times a minute

- Radial and Axial Bearings keeps the rotor suspended

- Fail-safe provision of sensors maintains reliability in operation

MODEL

| With Single Compressor | With Two Compressor | With Three Compressor | |||

|---|---|---|---|---|---|

| Model No. | Nominal TR (kW) | Model No. | Nominal TR (kW) | Model No. | Nominal TR (kW) |

| KCM 300.14 | 94 (331) | KCM 300.24 | 189 (665) | KCM 400.34 | 470 (1653) |

| KCM 350.14 | 130 (457) | KCM 350.24 | 261 (918) | KCM 700.34 | 612 (2152) |

| KCM 400.14 | 157 (552) | KCM 400.24 | 314 (1104) | ||

| KCM 700.14 | 193 (679) | KCM 700.24 | 385 (1354) | ||